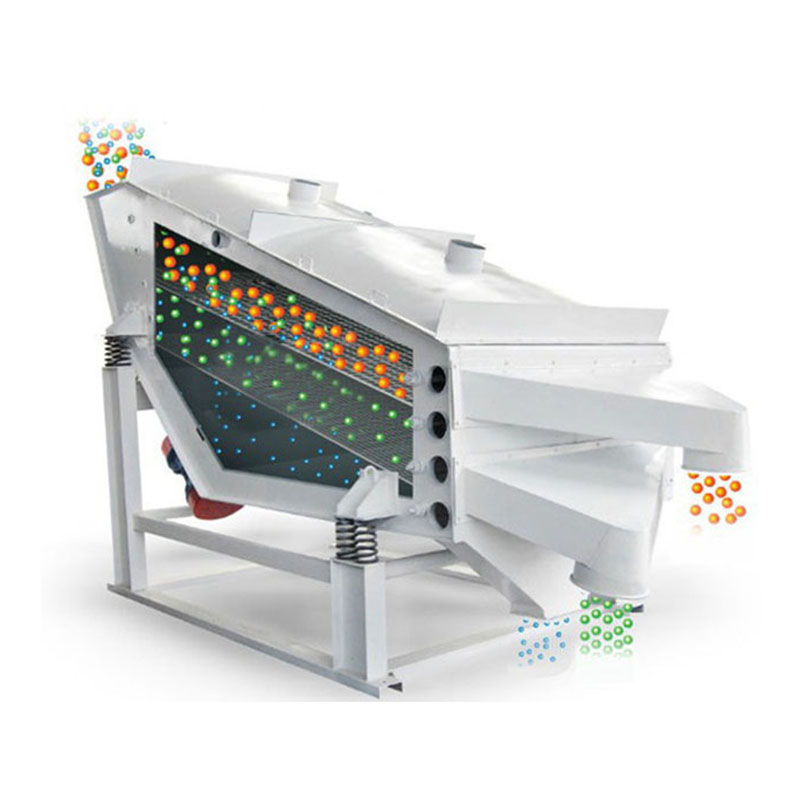

Working principle

Mine linear screen adopts domestic and foreign technologies such as vibration motor excitation, rubber spring vibration reduction, high wear-resistant material sieve plate, sealed screen box and other domestic and foreign technologies and synchronous vibration principle. It has the characteristics of long life, low noise and high screening efficiency. It is suitable for A vibrating screening equipment for sinter, natural ore, coke and other powdery materials.

Mine linear screen is mainly used in metallurgy, mining, coal, building materials, electric power, chemical industry and other industries, especially in the metallurgical industry, it is widely used in blast furnace trough, coking plant, and mineral processing plant.

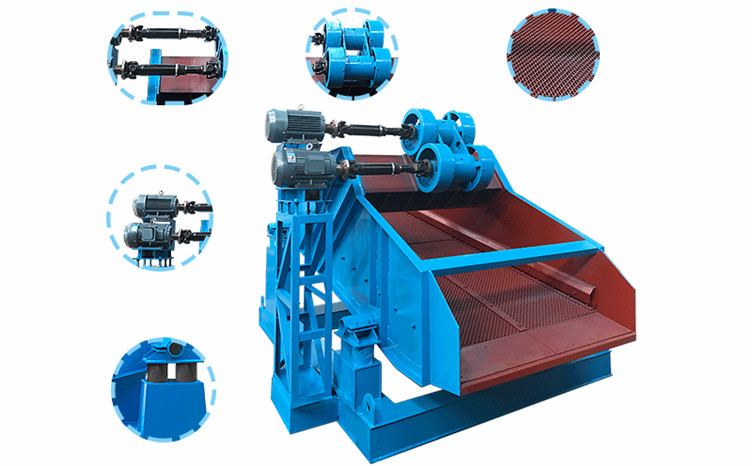

Product advantages

● Large processing capacity and high screening efficiency.

● The vibrator is lubricated with thin oil bearing and has an eccentric structure with an external block. It has the characteristics of large exciting force, small bearing load, low temperature and low noise. (Bearing temperature rise is less than 35°).

● The vibrator is disassembled and assembled as a whole, which is convenient for maintenance and replacement, which greatly shortens the maintenance cycle. (It only takes 1 to 2 hours to replace the vibrator).

● The side plate of the screen machine adopts the whole plate cold work, no welding, high strength and long service life. The connection between the beam and the side plate adopts torsional shear high-strength bolt connection, no welding, and the beam is easy to replace.

● The screening machine adopts rubber spring for vibration reduction, which has the advantages of low noise, long service life, stable passing through the common vibration area, and small dynamic load of each pivot point of the screening machine compared with metal springs.

● The connection between the motor and the exciter adopts a flexible coupling, which has the advantages of long service life and small impact on the motor.

Technical parameters

| Model | L(mm) | B(mm) | H(mm) | Feed particle size(mm) | Processing capacity(t/h) | Motor model | Motor efficiency(kW) | Total reference weight(kg) | Double amplitude(mm) |

| CFKS918 | 1810 | 1420 | 1575 | ≤120 | 50~100 | YZO-20-6 | 1.5X2 | 1710 | 5~10 |

| CFKS0924 | 2400 | 1370 | 1630 | 50~100 | YZO-20-6 | 1.5X2 | 1900 | ||

| CFKS1020 | 2000 | 1620 | 1584 | ≤150 | 50~100 | YZO-20-6 | 1.5X2 | 2070 | |

| CFKS1030 | 3000 | 1620 | 1800 | 50~100 | YZO-25-6 | 1.8X2 | 2630 | ||

| CFKS1224 | 2400 | 2190 | 1320 | 80~200 | YZO-30-6 | 2.2X2 | 2300 | ||

| CFKS1230 | 3000 | 2190 | 1800 | 80~200 | YZO-40-6 | 3.0X2 | 2863 | 8~12 | |

| CFKS1530 | 3000 | 2490 | 2180 | 120~300 | YZO-50-6 | 3.7X2 | 3690 | 5~10 |

Product details

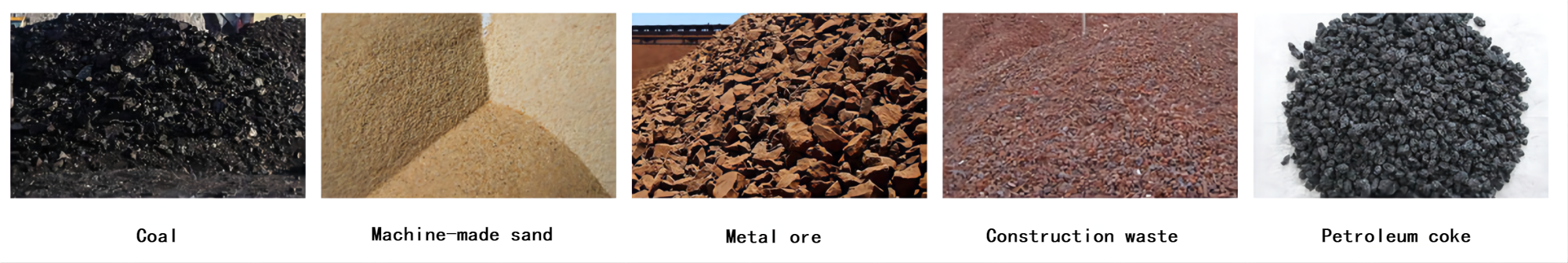

Application range

Metallurgical industry, mining industry, coal industry, building materials industry, chemical industry.

Application material

It is mainly used in the screening industries of metallurgy, mining, coal, building materials, electric power, chemical industry, etc. for large bulk materials and medium and small particle materials, especially in the metallurgical industry. mechanical.