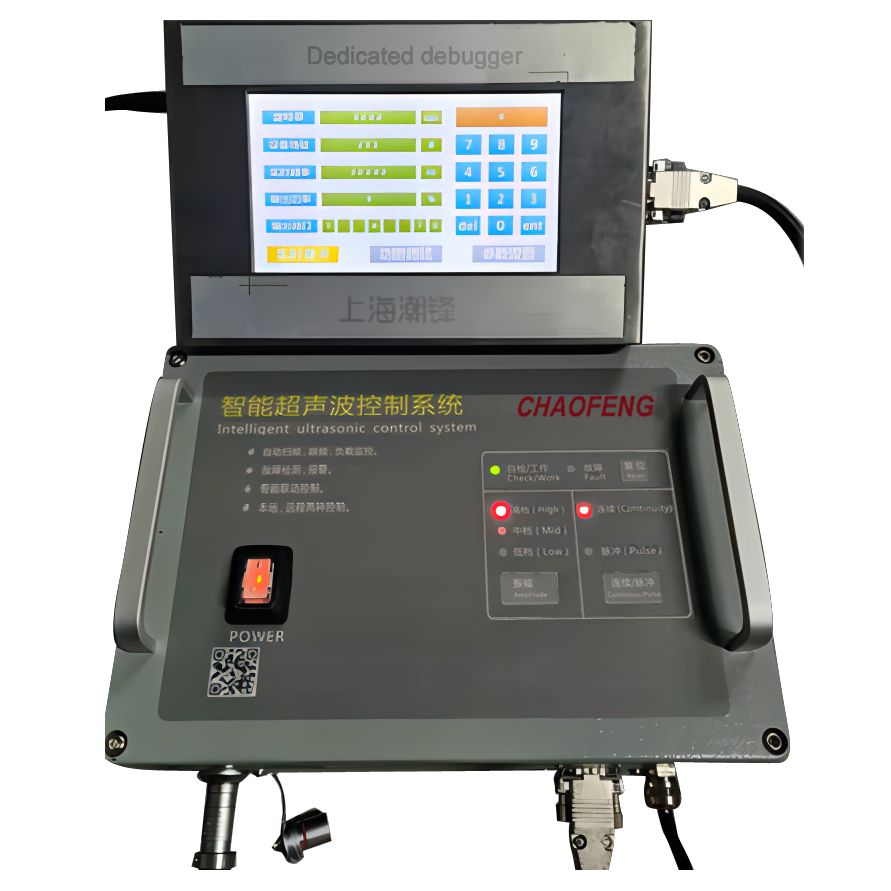

| Model | Rated voltage | Output frequency | Output Power | Working humidity | Dimensions |

| CF-35E | 220V | 28Khz-35Khz | 30W-150W | 0-90% | 295*210*147mm |

| Overview: | The ultrasonic system consists of three parts: ultrasonic generator, transducer and connecting line. It is widely used in various screening equipment to achieve the effect of cleaning the net and improving the production capacity. | ||

| mesh | output | layers | |

| 2-2500# | According to the characteristics of the material and the mesh number of the screen, it is 2-3 times the capacity of the ordinary screening machine. | 1-5layer | |

| Feareture: | Really solve the screening problems such as strong adsorption, easy agglomeration, high static electricity, high precision, high density and light specific gravity; | ||

| Application material: | Suitable for 400 mesh, 500 mesh, 600 mesh sieving silicon carbide, alloy powder, molybdenum powder, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating, quartz powder, butomidone powder, malt powder, ribavirin, Coffee powder, electromagnetic powder, negative electrode material, laser powder. In summary, the ultrasonic vibrating screen has a good screening effect on high-fine materials. | ||

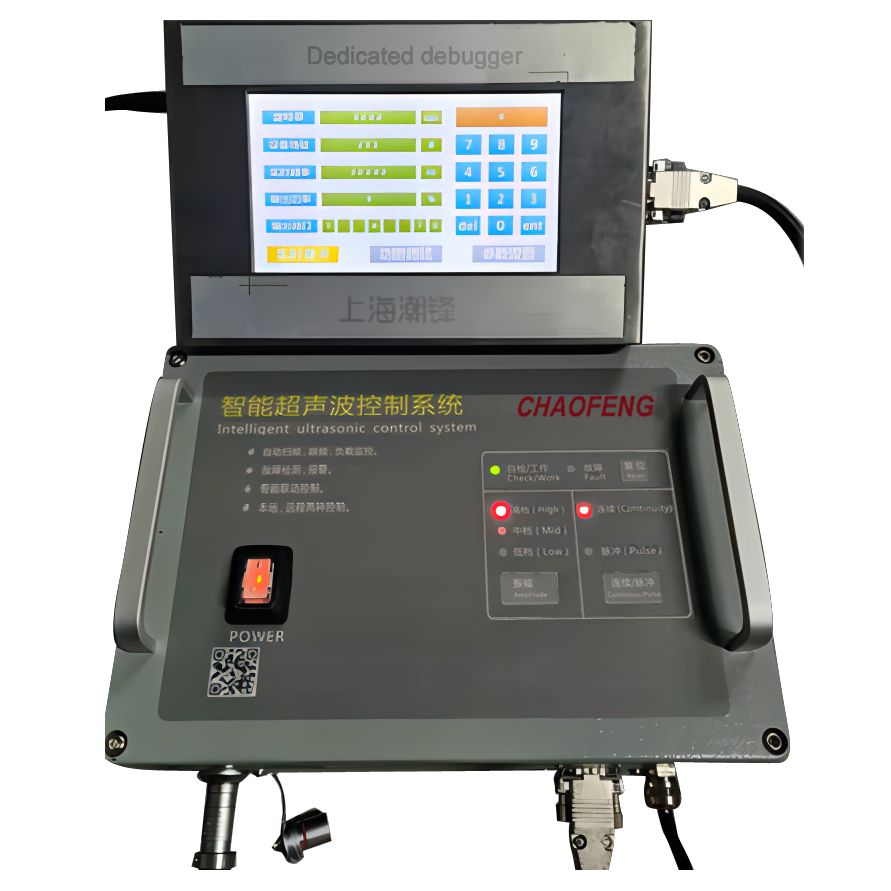

| Model | Rated voltage | Output frequency | Output Power | Working humidity | Dimensions |

| CF-35E | 220V | 28Khz-35Khz | 30W-150W | 0-90% | 295*210*147mm |