Working principle

The trommel screen is mainly composed of a motor, a reducer, a trommel device, a frame, a sealing cover, and an inlet and outlet. The roller unit is mounted on the frame at an angle. The motor is connected with the drum device through the reducer through the coupling, and drives the inclination and rotation of the drum device, so that the material on the screen surface is turned over and rolled, so that the qualified material (product under the screen) is discharged through the outer screen of the drum. Unqualified materials (on-screen products) are discharged through the end of the drum. Due to the turning and rolling of the material in the drum, the material stuck in the screen hole can be ejected to prevent the screen hole from being blocked.

Classification of trommel screen:

1. Classify according to whether there is a central axis structure

Shafted trommel screen can screen granular, powder, agglomerated materials, and shaftless trommel screen adopts shaftless design, which can screen and Screening, the yield will be increased by 20% compared with the shaft.

2. Classification according to the shape and structure

It can be divided into closed type and open type (cage type trommel screen). The closed type trommel screen can protect the cleanliness of the surrounding environment, and can also protect the screened materials from the influence of the external environment, which meets the requirements of the environmental protection industry.

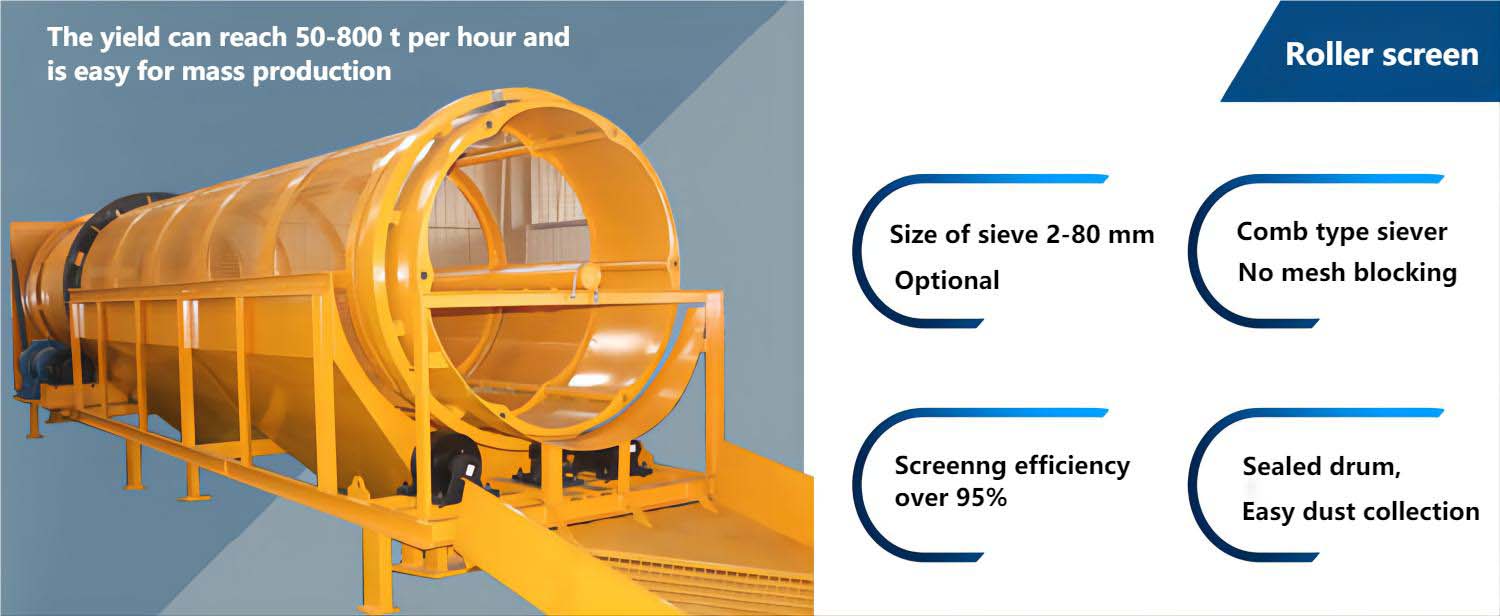

Product advantages

● The screen hole of the trommel screen is not easy to be blocked;

● Balanced operation and low noise;

● Simple structure, easy maintenance;

● High reliability of the whole machine, less one-time investment;

● Adopt special screen, which has high screening efficiency and long service life.

Comparison of advantages and disadvantages of trommel screen and vibrating screen

| Sieve Project | Trommel screen | Flat vibrating screen | Cantilever vibrating screen |

| Applicable coal | Various types of coal | Coal without impurities | Coal without impurities |

| coal feeding method | Various, depending on the actual situation | Only suitable for belts and funnels, the size of the coal inlet is fixed | Only suitable for belts and funnels, the size of the coal inlet is fixed |

| Screening method | rotate | vibration | vibration |

| Screening efficiency | above 95% | 10%-70%, depending on the moisture content of the coal | 10%-80%, depending on the moisture content of the coal |

| Sieve amount | Up to 100% MCR, unlimited | 10%-80% MCR, depending on the moisture content of the coal | 10%-80% MCR, depending on the moisture content of the coal |

| Cutting particle size | 6-30mm, can be adjusted arbitrarily | The cutting particle size cannot be adjusted arbitrarily and has exceeded the standard | The guarantee of the cutting particle size is not good, and there is a phenomenon of exceeding the standard |

| large-scale | The size is limited, small and easy to enlarge | Large-scale is limited by size, screening efficiency, etc. | Upsizing is limited by size efficiency and cantilever material |

| energy consumption | Small, 50% of other sieve types | Big | larger |

| noise | With sealed isolation cover, low noise | high | high |

| Equipment life | long | short | short |

| Screening mechanism | have | without | without |

| working environment | Yes, with hermetic isolation cover | Poor, no sealing isolation housing | Poor, no sealing isolation housing |

| Labor intensity | Small, no need for regular cleaningclean coal | Large, the equipment runs for a long time, and the ground coal is cleaned and cleaned. | Large, the equipment runs for a long time, and the ground coal is cleaned and cleaned. |

| Maintenance and wearing parts | The maintenance is small, and the wearing parts only need to replace the bearing | Large amount of maintenance, many wearing parts, screen mesh, vibration motor | Large amount of maintenance, many wearing parts, screen bars, vibration motors |

| Guaranteed value of coal on boiler | 100% | not fully guaranteed | not fully guaranteed |

Technical parameters

| Model | Processing capacity(t/h) | Power(kw) | Screen barrel diameter(MM) | Screen barrel length(MM) | Under sieve particle size(MM) | Overall dimension(MM) | Weight(kg) |

| CF-GTS-1020 | 50 | 5.5 | 1000 | 2000 | <3~10 | 3000*1400*2145 | 2200 |

| CF-GTS-1030 | 100 | 5.5 | 1000 | 3000 | 3460*1400*2145 | 2800 | |

| CF-GTS-1225 | 160 | 7.5 | 1200 | 2500 | 4146*1600*2680 | 4200 | |

| CF-GTS-1530 | 250 | 11 | 1500 | 3000 | 4460*1900*2820 | 5100 | |

| CF-GTS-1545 | 350 | 15 | 1500 | 4500 | 5960*1900*3080 | 6000 | |

| CF-GTS-1848 | 450 | 22 | 1800 | 4800 | 6500*2300*4000 | 7500 | |

| CF--GTS-2055 | 600 | 30 | 2000 | 5500 | 7500*2500*4000 | 8600 |

Note: 1. The external dimensions are calculated according to the length of the cylinder; 2. The processing capacity is calculated according to the large aperture; 3. The angle of inclination and the length of each section are different depending on the material; 4. The quality is calculated according to the length of the cylinder and the woven mesh is used 5. The proportion of large pieces of material shall not exceed 10%

Product details

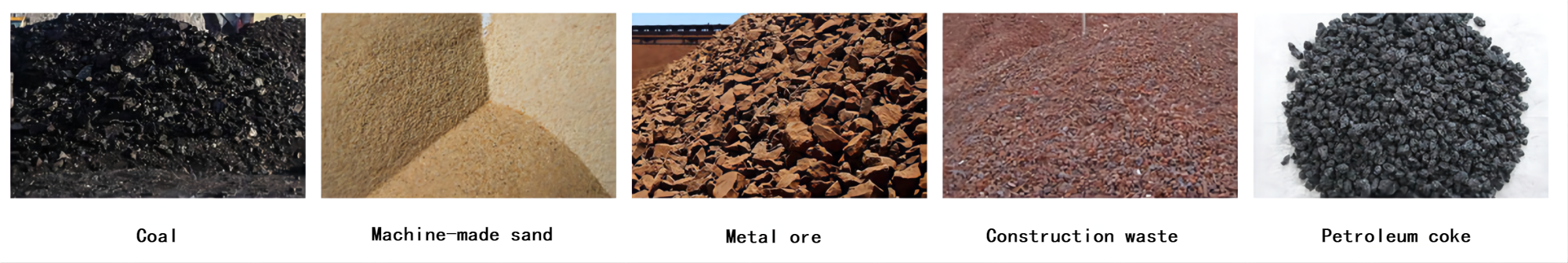

Application range

1. In the stone quarry, it is used for grading large and small stones and separating soil and stone powder.

2. It is used for sand and gravel separation in sand and gravel fields.

3. The coal industry is used for the separation of lump coal and pulverized coal and for coal washing (a component of coal washing machinery).

4. The chemical industry and mineral processing industry are used for the classification of large and small blocks and the separation of powdery substances.