Working principle

In-line vibrating screen is also called in-line vibrating screen. It is divided into single vibration source and double vibration source. It is improved on the basis of the function of circular vibrating screen. It uses two vibration motors as vibration sources. It enters the feeding port in the middle, and is directly discharged from the middle discharge port at the bottom through screening, which is suitable for the restriction of installation conditions or continuous operation in large quantities. It can meet the good screening effect of various materials with different specific gravity. It is mainly used for impurity removal and sieving loosening of powder in the process flow of powder production line.

In-line screen, a single horizontal vibration motor is used as the excitation source, and the vibration motor is placed on one side of the body. After the material enters the equipment, it is subjected to the force of the vibration source to make an elliptical motion track on the screen surface. At the same time as the rapid and reciprocating action of passing the net is completed, the vibration force can continuously and continuously peel, disperse and reorganize the material, so that the material can pass through the net quickly. It is discharged from the mouth to complete the screening process.

Product advantages

● Flat design of straight screen equipment, easy for manual operation, small size and easy to move;

● The straight screen can be connected to the production line system in series, with low energy consumption and high efficiency;

● Easy to clean inside and outside, no hygienic dead corners, in line with food and pharmaceutical industry standards;

● Automatic operation of in-line sieve, 24-hour continuous production;

● The straight screen is tightly sealed, the liquid does not leak, and the dust does not fly;

The unique structure and mesh frame design of the in-line screen can improve the durability of the screen, the screen change is fast, and the disassembly and assembly are convenient, so that the screen change problem can be completed within 5 minutes;

Technical parameter

| Model | Effective screen diameter(mm) | layer | Motor Power (KW) | Dimensions (Lmm*Wmm*Hmm) |

| CF-ZPS-106 | 560 | 1 | 0.15kw*2 | 740*600*560 |

| CF-ZPS-108 | 760 | 1 | 0.37kw*2 | 1010*800*600 |

| CF-ZPS-110 | 930 | 1 | 0.40kw*2 | 1200*970*640 |

| CF-ZPS-120 | 1130 | 1 | 0.40kw*2 | 1430*1170*700 |

| CF-ZPS-115 | 1430 | 1 | 0.55kw*2 | 1780*1470*760 |

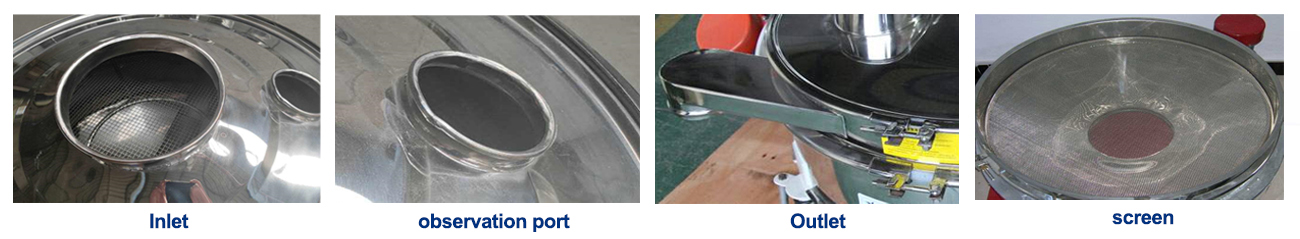

Product Details

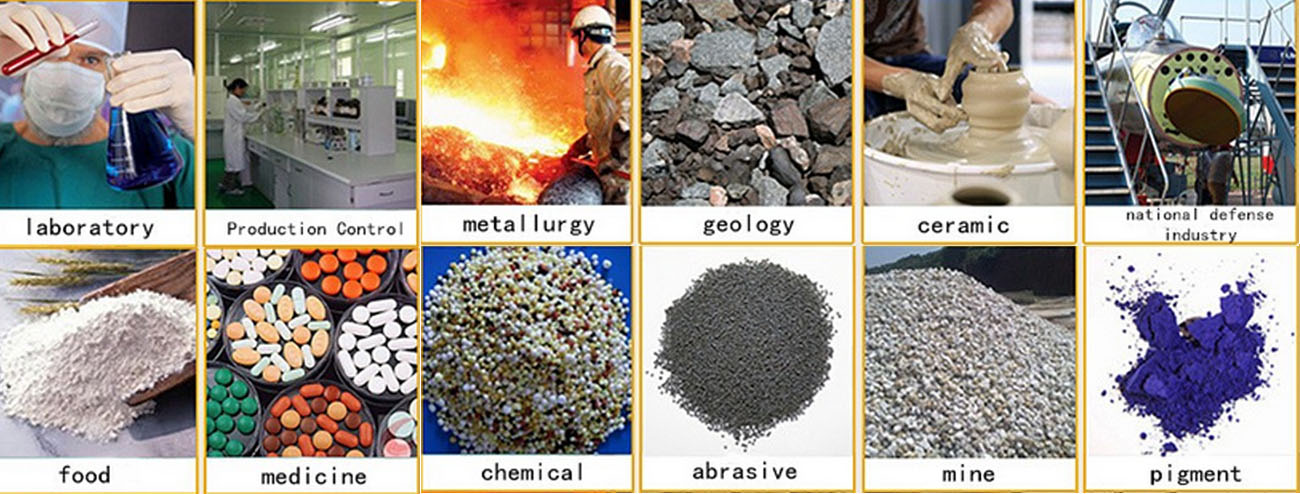

Application range

Food industry, pharmaceutical industry, chemical industry, metal, metallurgical mining, non-metal industry, other industries, etc.

Application materials:

Flour, starch, milk powder, additives, carbon black (silica), quartz powder (sand), mica, fluorescent powder, feldspar powder, kaolin, silica black clay, fly ash, glass beads, environmental protection, plastic, plastic, magnetic materials, building materials, mining, kiln industry, feed, condiments, fish meal, rice flour, flour, soybean meal, milk powder, egg powder, starch, sugar, fruit juice, western medicine powder, traditional Chinese medicine powder, pharmaceutical intermediates, pearl powder, soda ash, poly Vinyl, Resin Powder (PVC, Epoxy), Laundry Powder, Auxiliary, Paint, Dyestuff, Pigment, Rubber, Coating, Alloy Powder, Gold Powder, Silver Powder, Copper Powder, Aluminum Powder, Nickel Powder, Chromium Powder, Magnesium Powder, Zinc Powder, barium powder, vanadium powder, titanium powder, strontium powder, lead powder, foundry sand, etc.