Product description

Ultrasonic system is composed of ultrasonic generator, high-frequency connecting cable, transducer and resonator. The ultrasonic power generator generates a high amount of current and converts it into a high-frequency sinusoidal longitudinal oscillating wave through the transducer. These oscillating waves are transmitted to the resonator to make the resonator resonate, and then the resonator transmits the vibration evenly to the screen surface.

The materials on the screen are subjected to low-frequency three-dimensional vibration and ultrasonic vibration, which can prevent the mesh from clogging, and can improve the screening output and accuracy.

Working principle

Ultrasonic system is a high-tech system that converts electrical energy into high-frequency vibration mechanical energy. This system successfully solves the difficult problems of material blocking and low screening efficiency encountered in the screening field, and is widely used in various powder equipment. superior. After a lot of tests and improvements, the matching of the ultrasonic generator and the transducer has reached an optimized state, which effectively solves the problem of the transducer heating, and can maintain a strong vibration energy output.

Function production

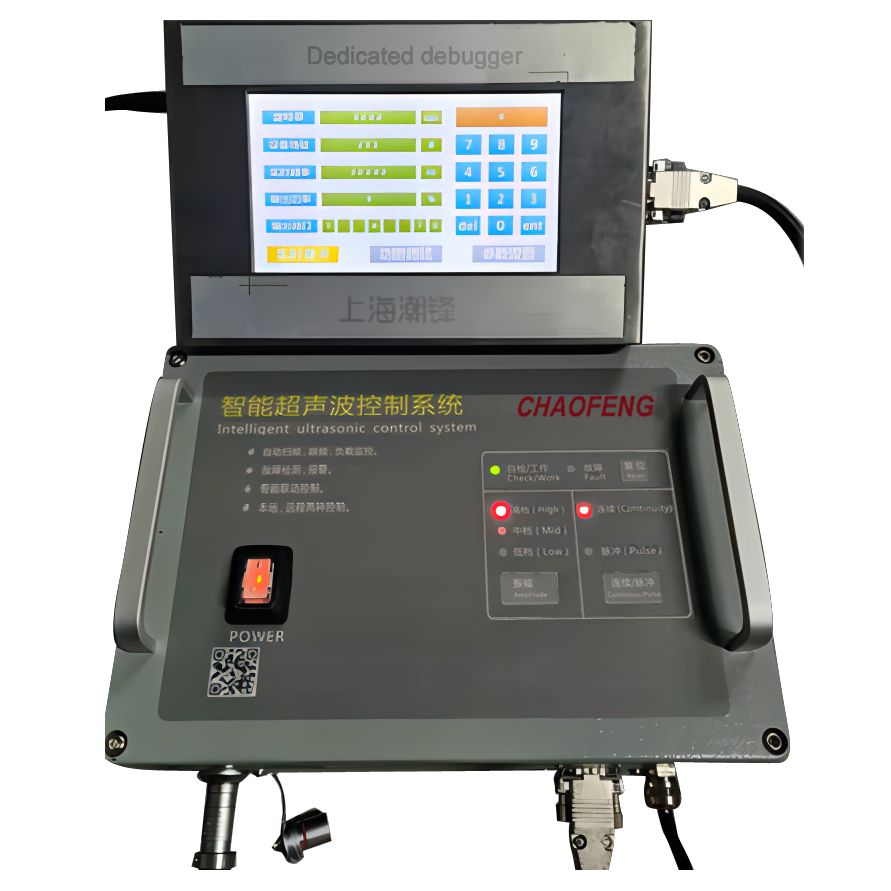

The ultrasonic generator can also become an ultrasonic power source. Its function is to provide stable and intelligent high-frequency power for the ultrasonic transducer, and it can control the power output mode and current intensity output intensity to achieve different ultrasonic modes and energy output. Require. There are two modes of Ruang ultrasonic generator: pulse, continuous. Three modes of power output intensity: high, medium and low.

The ultrasonic screening system is a simple, practical and reliable screening system, and it is an effective solution to the current mesh blockage. It can be widely used in pharmaceutical, metallurgy, chemical, mineral processing, food and other industries that require fine screening and filtration. It has high screening and filtration accuracy and can effectively solve screening problems due to agglomeration, static electricity, and strong adsorption. A major breakthrough in the sub-industry.

Structure

link cable -- a cable link is used between the ultrasonic transducer and the power supply of the ultrasonic vibrating screen.

Connector -- Aviation link plug-in.

Transducer - high performance ultrasonic conversion device.

Ultrasonic grid frame - composed of external grid frame and resonator.

Screen -- suitable for 10 mesh to 800 mesh.

Product advantages

●The circuit uses advanced IGBT power devices and high-speed DSP chips, and uses single-chip intelligent control.

●Automatic frequency tracking function, which can be automatically matched according to the situation of use.

●With fault alarm function, if the ultrasonic work is abnormal during use, the generator can automatically identify it, output an alarm indication, and cut off the ultrasonic output at the same time.

●Ultrasonic output power (amplitude) is divided into high, medium and low adjustable.

●The ultrasonic output mode is divided into continuous and pulsed, and the pulse is tentatively turned on 2S and off 2S.

●Retain remote operation interface, which is convenient for customers to control and use.

●Linkage control of upstream and downstream equipment, integrated monitoring system.

●The system is equipped with a static elimination device, which can guide away the static electricity generated by the material during the cleaning process.

Device parameters

| Model | Rated voltage | Output frequency | Output Power | Working humidity | Dimensions |

| CF-35E | 220V | 28Khz-35Khz | 30W-150W | 0-90% | 295*210*147mm |