Working principle

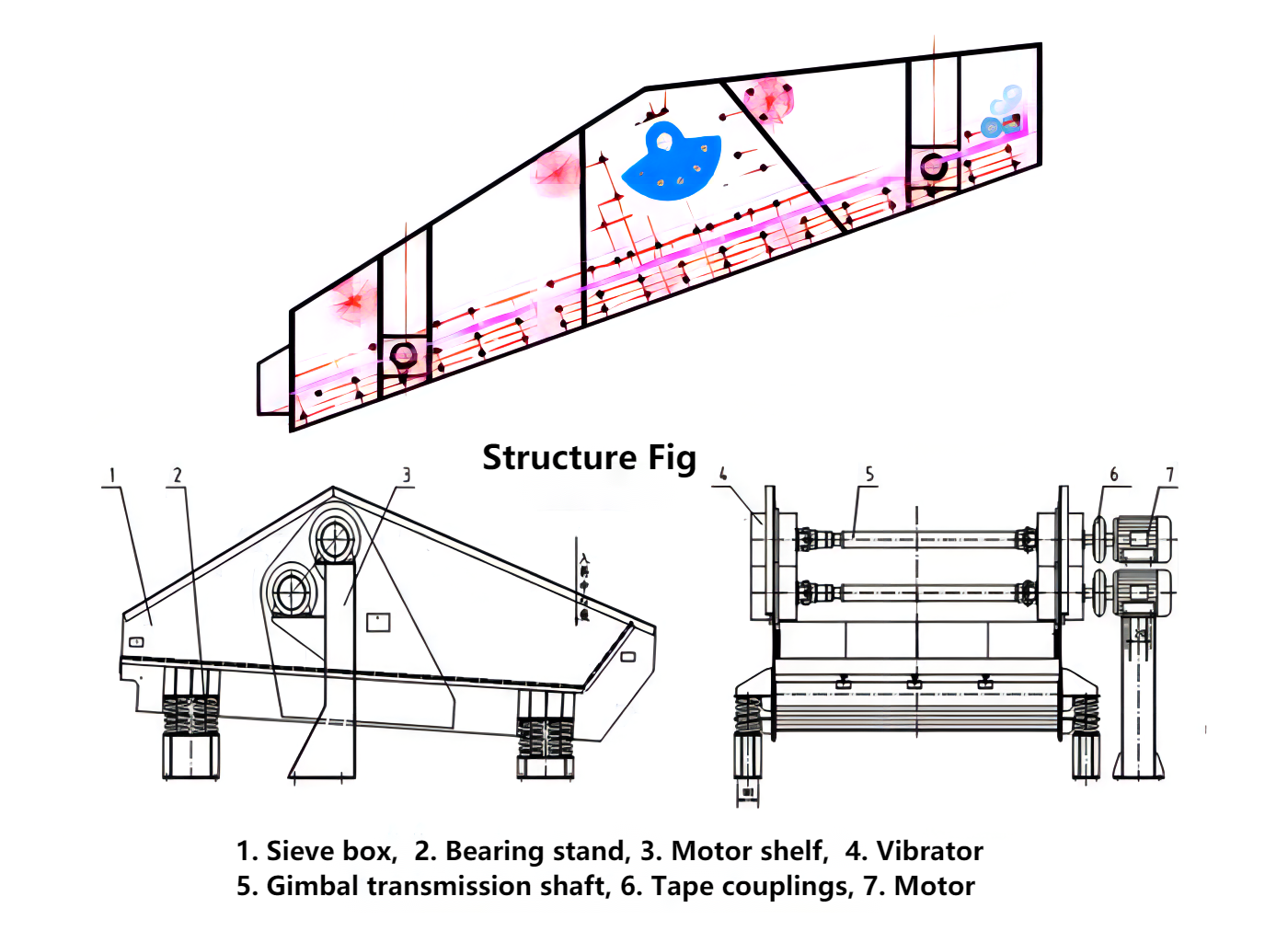

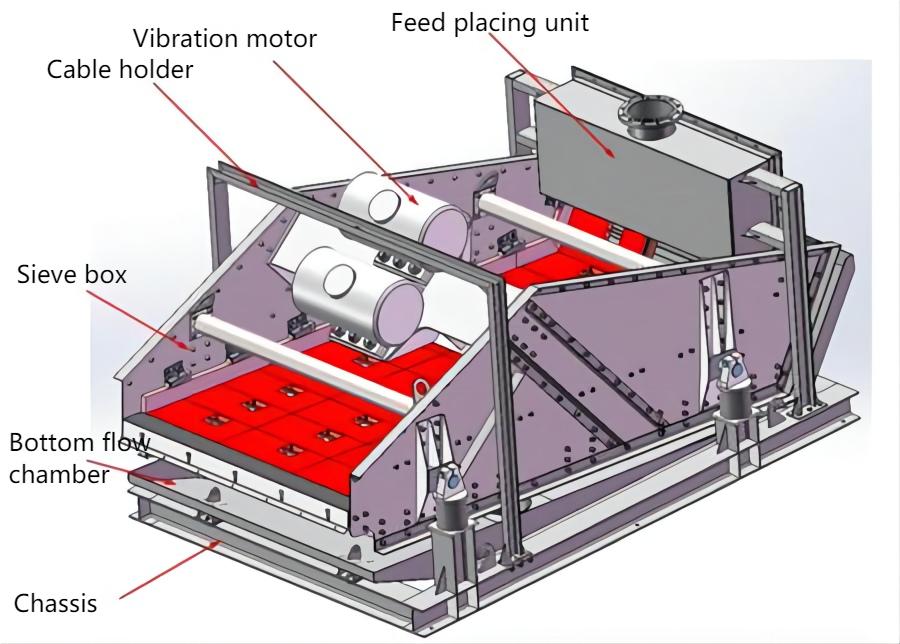

Dewatering screen is mainly used for dehydration, desliming and de-intermediation. It can be used for sand washing in sand and gravel plant, coal slime recovery in coal preparation plant, dry discharge of tailings in mineral processing plant, etc., so it is also called sand and gravel dewatering screen, mine dewatering screen, Coal slime dewatering screen, tailings dry discharge screen, high frequency dewatering screen, etc. The dewatering screen adopts dual-electrode self-synchronization technology, which is composed of screen box, vibration exciter (or vibration motor), support system and motor. The two unconnected vibrators are driven by the belt coupling for synchronous and reverse operation. The centrifugal force generated by the two sets of eccentric masses is superimposed along the vibration direction, and the reverse centrifugal force is counteracted, thereby forming a single excitation vibration along the vibration direction. , so that the screen box does a reciprocating linear motion. According to the washing and dewatering requirements of different materials, the dewatering screen is designed with different screen inclination angles and screen plate forms to improve the dewatering production efficiency and ensure the dewatering effect. The dewatering screen can be installed on the left or right of the excitation source according to the location of the production site, which is convenient for the layout of the production process. The dewatering screen dewaters and drains the tailings slurry, such as the mixed slurry of coal slime, to reduce the energy loss of the dryer.

Product advantages

1. The relative volume is small, the processing capacity per unit area is large, and the system process layout is convenient. 2. The professionally designed frequency, amplitude and low power consumption are suitable for 24-hour continuous dry discharge operation of various dehydration requirements. 3. V-shaped screen surface design, -5゜ sieving surface climbing dehydration, dry tailings with low water content and high efficiency. 4. The high wear-resistant sieve plate has a long service life, modular assembly design, and easy replacement. 5. The way of riveting and welding the profiled steel components constitutes a frame body with no internal stress, high strength, light weight and durability.

1. The relative volume is small, the processing capacity per unit area is large, and the system process layout is convenient. 2. The professionally designed frequency, amplitude and low power consumption are suitable for 24-hour continuous dry discharge operation of various dehydration requirements. 3. V-shaped screen surface design, -5゜ sieving surface climbing dehydration, dry tailings with low water content and high efficiency. 4. The high wear-resistant sieve plate has a long service life, modular assembly design, and easy replacement. 5. The way of riveting and welding the profiled steel components constitutes a frame body with no internal stress, high strength, light weight and durability. Technical parameters

| Model | Screen area(m³) | Motor power(kw) | Processing capacity(m³/H) | Feed particle size(MM) | Overall dimension(MM) | Weight(t) |

| CF-TSS0720 | 1.4 | 0.75*2 | 5-10m³ | ≤10 | 2300*1000*750 | 0.8 |

| CF-TSS9020 | 1.8 | 1.1*2 | 10-20m³ | 2300*1200*750 | 1.2 | |

| CF-TSS1020 | 2 | 1.1*2 | 10-30m³ | 2300*1300*750 | 1.6 | |

| CF-TSS1225 | 3 | 1.5*2 | 50-80m³ | 2800*1200*800 | 2.1 | |

| CF-TSS1230 | 3.6 | 2.2*2 | 60-90m³ | 3300*1500*800 | 2.6 | |

| CF-TSS1530 | 4.5 | 3*2 | 100-120 | 3300*1800*800 | 3.2 |

Product details

Application range

Mine dewatering screen is a special vibrating screen for coal slime dewatering operation. It is widely used in coal preparation, electric power, mineral processing, salt production, chemical industry, sugar production and other industries. Coarse, filter press, dewatering of other ultra-fine materials, filtration, coarse dewatering, de-intermediation, desliming and recovery processes. Application material Iron tailings, gold tailings, copper tailings, graphite tailings, quartz sand, zircon sand, glass sand, construction sand, foundry sand, coal slime dewatering municipal sewage, industrial sewage, solid-liquid separation of river sludge, sewage Filtration of treatment plants. Conditions of use of mine dewatering screen (1) The vibration acceleration does not exceed 20g (g: 9.8m/s gravitational acceleration); (2) The ambient temperature does not exceed 40°C (if it exceeds 40°C, the power should be reduced); (3) The altitude does not exceed 1000 meters. When the altitude exceeds 1000 meters, the temperature rise limit should be reduced by 0.5℃ for every 100 meters higher; (4) Power supply: three-phase 380V, frequency 50Hz; (5) Working mode: SI (continuous); (6) The temperature rise value of the stator winding (resistance method) does not exceed 80K; (7) The allowable temperature of the bearing (thermometer method) should not exceed 95 °C; (8) The working current of the main engine does not exceed the data on the motor nameplate, otherwise the excitation force is reduced; (9) The operating environment of the mine dewatering screen should be free of conductive dust, flammable, explosive and corrosive gases.

(1) The vibration acceleration does not exceed 20g (g: 9.8m/s gravitational acceleration); (2) The ambient temperature does not exceed 40°C (if it exceeds 40°C, the power should be reduced); (3) The altitude does not exceed 1000 meters. When the altitude exceeds 1000 meters, the temperature rise limit should be reduced by 0.5℃ for every 100 meters higher; (4) Power supply: three-phase 380V, frequency 50Hz; (5) Working mode: SI (continuous); (6) The temperature rise value of the stator winding (resistance method) does not exceed 80K; (7) The allowable temperature of the bearing (thermometer method) should not exceed 95 °C; (8) The working current of the main engine does not exceed the data on the motor nameplate, otherwise the excitation force is reduced; (9) The operating environment of the mine dewatering screen should be free of conductive dust, flammable, explosive and corrosive gases.