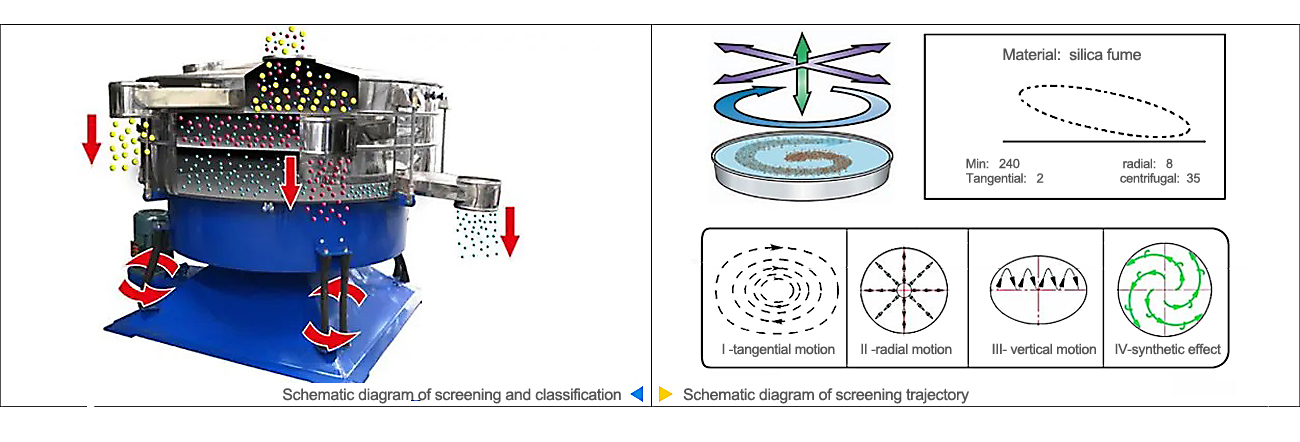

Working principle

The swing sieve is a low-frequency vibrating screen that directly imitates artificial screening. Its motion trajectory is the combination of the radial displacement of the instantaneous motion and the circular motion of this displacement as the axis. The non-linear three-dimensional motion can be generated by adjusting the eccentric distance of the exciter, and the movement of the material on the screen surface is similar to manual screening, so as to achieve the effect of screening the material. The screen body is equipped with a unique net cleaning device. , in order to achieve effective screening effect, especially suitable for precision screening of cylindrical, flake and other irregular shaped materials.

The swing sieve is a kind of low-frequency rotary vibrating screen that imitates artificial shaking. In addition to nonlinear three-dimensional motion, the material also produces the same motion that is similar to manual operation, so as to achieve the purpose of screening.

Product advantages

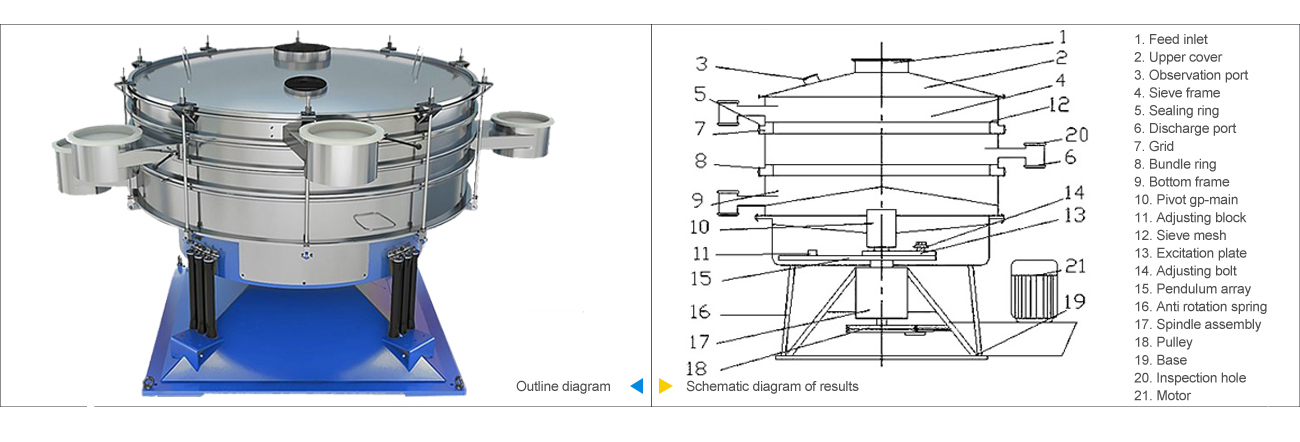

● It can realize single-layer or multi-layer high-efficiency screening and can screen 6 particle sizes. Up to 5 layers, while providing 5 to 6 groups of grading.

● The principle of the swing screen is actually a mechanical simulating manual hand screen. Gentle acceleration and low speed operation ensure that the material rolls on the screen surface. noodle. Especially for dry, low-density particles; it can also effectively reduce the wear of the sieve itself (screen) for highly abrasive products.

● Each layer of screen mesh realizes accurate classification of coarse and fine particles. The material is fed from the center of the horizontal screen body and spreads out to the periphery along the spiral line. At the same time, as the vertical acceleration increases, the finer product is forced to effectively penetrate the screen surface.

● Effectively reduce the damage of fragile materials. Hand screen can give gentle treatment to materials. The shaker perfectly reproduces the same movement and is used in applications where particle breakage is prohibited, such as: spray-dried coffee, powdered products of biopharmaceuticals, as well as milk powder and metal powders.

● Effectively reduce maintenance time as fast as 15 minutes Simple and quick disassembly and installation.

Technical parameter

| Model | Effective area | Effective screen diameter | layers | Motor Power | Related dimensions | cleaning system |

| CF-YBS-112 | 1.13 | 1250 | 1--5 | 2.2kw | 1250*1110 | bouncing ball drum brush Ultrasonic |

| CF-YBS-116 | 1.83 | 1580 | 1--5 | 3kw | 1580/1400 | |

| CF-YBS-118 | 2.43 | 1778 | 1--5 | 3kw | 1778/1412 | |

| CF-YBS-120 | 2.63 | 1880 | 1--5 | 4kw | 1880/1800 | |

| CF-YBS-126 | 5.3 | 2560 | 1--5 | 5.5kw | 2650/1900 |

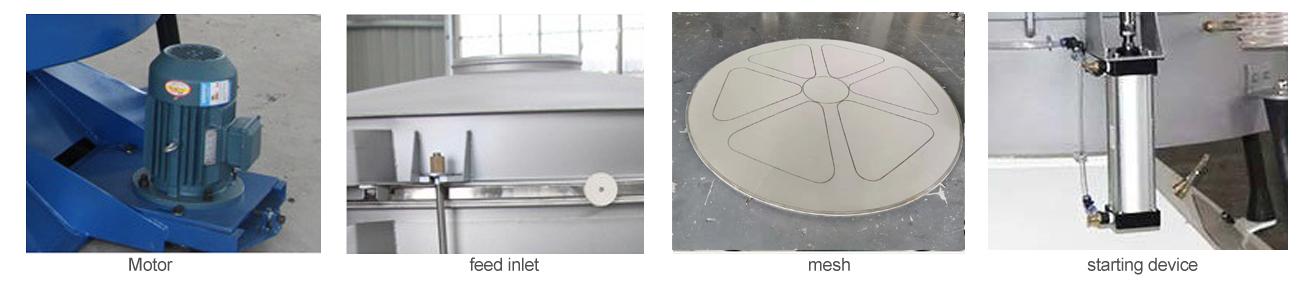

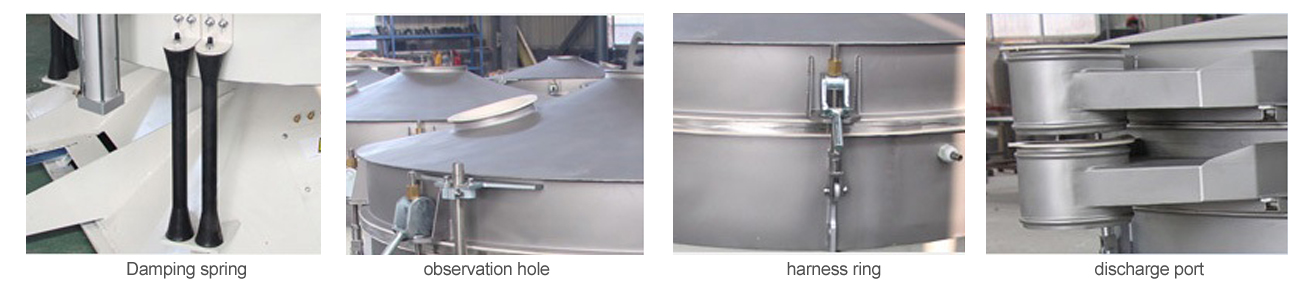

Product Details

Application range

Chemical Industry Pharmaceutical Industry Ceramic Abrasive Metallurgical Industry

Application material

Paint, resin powder, PVC resin powder, citric acid, polyethylene powder, washing powder pharmaceutical intermediates, medical excipients, traditional Chinese medicine powder, traditional Chinese medicine liquid, western medicine powder, western medicine liquid, aluminum silver paste, mud, kaolin, quartz sand , alumina, artificial black aluminum, graphite, silicon carbide, spray soil particles, emery, iron powder, titanium dioxide, electrolytic copper powder, etc.