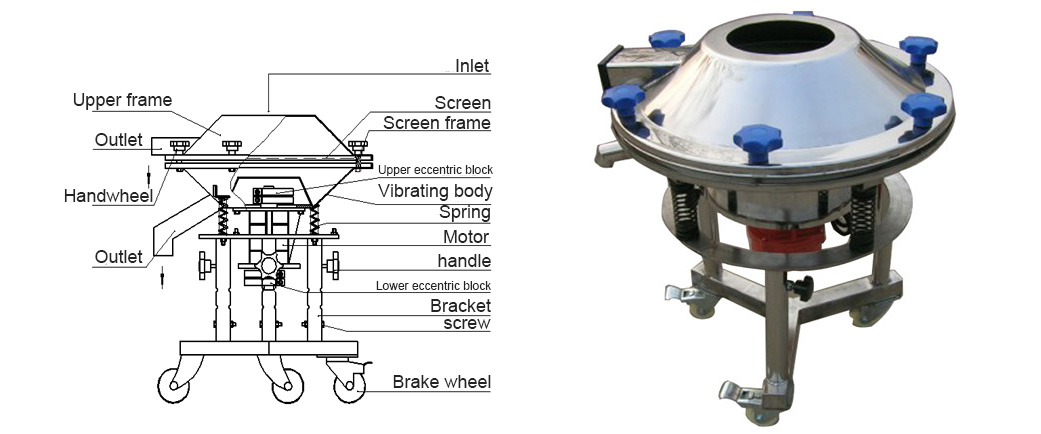

Working principle

High-frequency vibrating screen, also known as high-frequency vibrating screen, is composed of exciter, screen frame, frame, suspension spring and screen mesh.

The high-frequency vibrating screen adopts a cylindrical eccentric shaft exciter and an eccentric block to adjust the amplitude. The material screen has a long flow line and a variety of screening specifications. It has reliable structure, strong excitation force, high screening efficiency, low vibration noise, sturdy and durable, Features such as convenient maintenance and safe use, high-frequency vibrating screens are used in product classification in food, medicine, chemical, new energy and other industries.

Because the high-frequency vibrating screen (high-frequency screen) adopts high frequency, on the one hand, it destroys the tension on the surface of the material and the high-speed oscillation of the fine-grained material on the screen surface, accelerates the effect of large-density materials and segregation, and increases the particle size smaller than the separation. The probability that the material will come into contact with the screen openings. Therefore, better separation conditions are created, so that the materials smaller than the separation particle size, especially the particles with large specific gravity, pass through the sieve holes together to become the under-sieve product.

Product advantages

● High-frequency vibration screening with high precision and high efficiency, can be used for any powder, granule and slurry;

● The high-frequency vibrating screen has no blockage, no powder flying, high vibration frequency, up to 3000 times/min, and has obvious sieving effect on fine-grained and high-viscosity materials; the equipment can effectively handle solid-mixed materials and quickly realize solid-liquid separate;

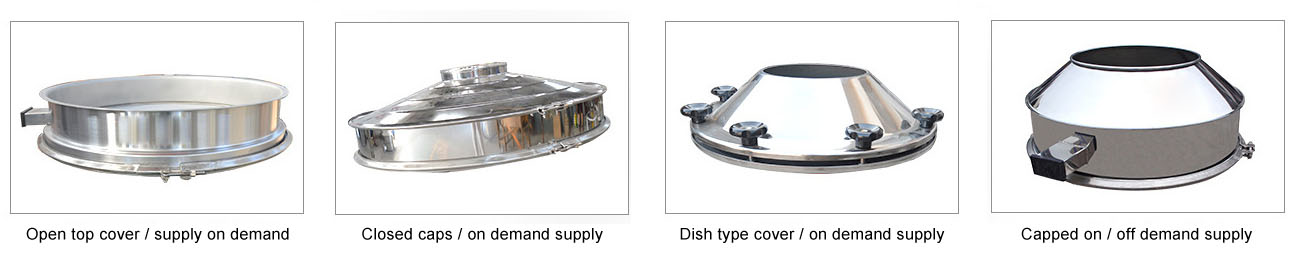

● The high-frequency vibrating screen has a unique screen structure, which is convenient and quick to install the screen, only 3 to 5 minutes, simple operation, convenient cleaning, no dead corners, and no residue;

● The high-frequency vibrating screen has no mechanical action and is easy to maintain. Except for the motor part, the rest are made of stainless steel;

● High efficiency, small amplitude, low noise and high screening frequency. Different from the principle of ordinary screening equipment, because the high-frequency screen adopts high frequency, on the one hand, it destroys the tension of the liquid surface and the high-speed oscillation of fine-grained materials on the screen surface, and accelerates the separation of useful substances with high density (specific gravity). , which increases the probability that the particles smaller than the separated particles are in contact with the sieve holes. Thereby resulting in better separation conditions, so that the materials smaller than the separation particle size, especially the particles with a large specific gravity, pass through the sieve holes together with the liquid to become the under-sieve product;

● Each high-frequency vibrating screen is equipped with a movable frame, which can be moved freely in the workplace, and the height can be adjusted without complicated installation, simple operation and not easy to damage;

Technical parameter

| Model | Outer frame diameter (mm) | Screen diameter (mm) | Screen mesh | Layer | frequency | power |

| CF-GPS-600 | 600 | 550 | 2-800 | 1 | 3000 | 0.55 |

| CF-GPS-800 | 800 | 760 | 2-800 | 1 | 3000 | 0.75 |

| CF-GPS-1000 | 1000 | 950 | 2-800 | 1 | 3000 | 1.1 |

| CF-GPS-1200 | 1200 | 1150 | 2-800 | 1 | 3000 | 1.5 |

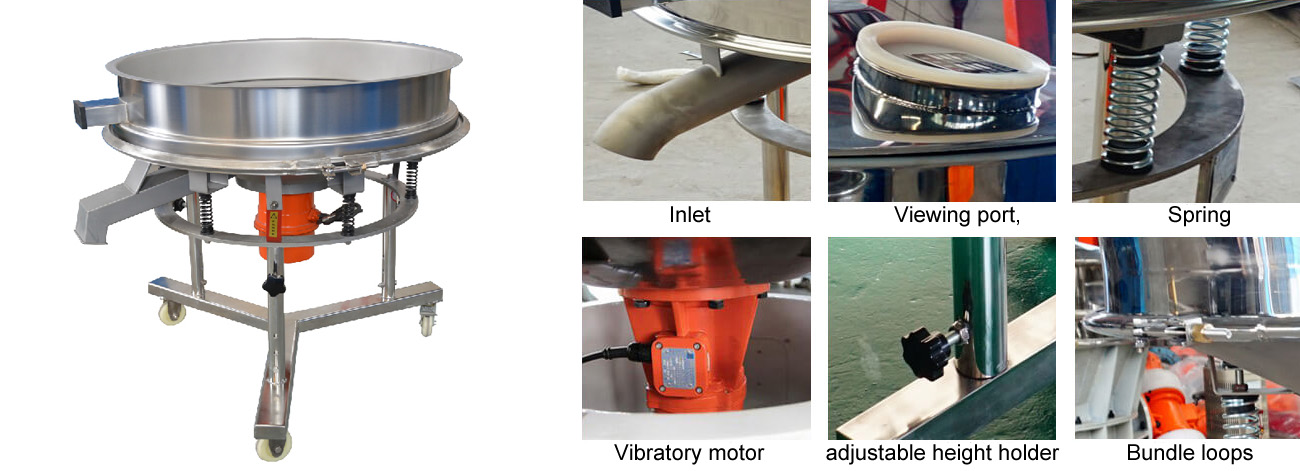

Product details

Application range

Materials: yeast, glaze, liquid paint, waste water treatment, filter grease, mud, waste water, waste oil, paint, ink, colorant, paint, Latex paint, aluminum powder slurry; starch, soy milk, fruit juice, beverages, dairy products, condiments; pulp, waste liquid, Chinese and Western medicine liquid.

Notes on high-frequency screening

1. Frequency: The vibration frequency of the high-frequency vibrating screen is about 50HZ. It is precisely because of this high-frequency vibration that the material can be quickly separated, which is suitable for materials with high slurry concentration.

2. Angle: the installation angle of the screen machine is convenient and adjustable, and the installation inclination angle of the wet screening in the concentrator is generally 25±2°

High frequency screen maintenance

1. When the equipment is in normal operation, the ore feeding concentration of the sieve should be observed frequently, and the concentration should be controlled at about 40% in order to improve the classification efficiency.

2. Because the screen has high classification efficiency, good dewatering performance and high concentration of over-screen amount, the slurry in the over-screen amount chute has poor fluidity, so it should be equipped with a water pipe.

3. The electromagnetic exciter and the control box should be strictly protected from water to avoid short circuit. Cover the exciter with a rubber sheet to prevent water and slurry from falling in, causing short circuits and blocking air gaps.

4. Check whether the bolts of various parts are loose at any time, and whether the screen frame collides with the chute.

5. Always pay attention that the pointer of the ammeter cannot exceed the rated value. When the screen machine is running for about half a month, the current value should be adjusted to near (usually 8-9A) and vibrated for 4-5 minutes, so as to shake off the objects on the back of the screen.

6. The excitation current (amplitude) can be adjusted according to the nature of the ore and the operation requirements. In order to make the sieve work under the condition of high efficiency, the excitation current condition test can be done.