Working principle

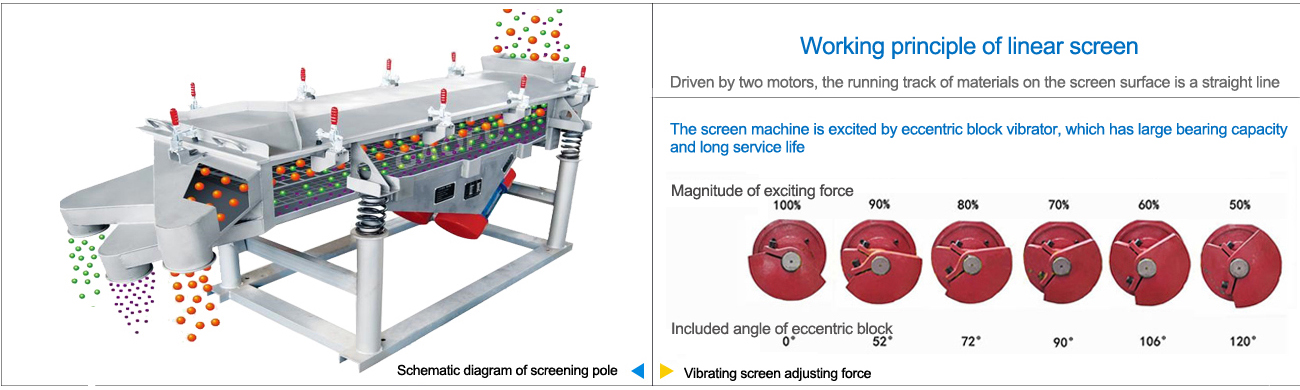

The linear screen is driven by double vibration motors, and the vibration motor is used to excite the screen mesh to vibrate. When the two motors rotate synchronously and in opposite directions, the exciting force generated by the eccentric block cancels each other in the direction parallel to the axis of the motor. Due to the resultant force in the direction of the motor shaft, the motion trajectory of the screen machine is a straight line at this time. The material is thrown up and jumped on the screen surface or moves forward in a straight line, so as to achieve the purpose of screening and grading the material. The linear vibrating screen uses the vibration of the vibration motor as the vibration source, and produces several specifications of the above and below the screen through the multi-layer screen, which are discharged from their respective outlets. It has low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust overflow, automatic discharge, and is more suitable for assembly line operations.

The linear vibrating screen uses the vibration of the vibration motor as the vibration source, and produces several specifications of the above and below the screen through the multi-layer screen, which are discharged from their respective outlets. It has low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust overflow, automatic discharge, and is more suitable for assembly line operations. Product advantages

● Grading and screening of various materials, the particles after screening are uniform in size and high in screening accuracy. ● Generally, the design of a single unit varies from 1 to 5 layers, and the required number of layers can be selected according to different needs. ● It has the advantages of convenient maintenance and relatively low maintenance probability. ● Using the vibration source with adjustable angle, the screen is clean; the multi-layer design can be used, and the screen can be more; it can be evacuated by negative pressure, and the environment is good. ●It has a unique effect on the screening and classification of powdery and granular materials.

● Grading and screening of various materials, the particles after screening are uniform in size and high in screening accuracy. ● Generally, the design of a single unit varies from 1 to 5 layers, and the required number of layers can be selected according to different needs. ● It has the advantages of convenient maintenance and relatively low maintenance probability. ● Using the vibration source with adjustable angle, the screen is clean; the multi-layer design can be used, and the screen can be more; it can be evacuated by negative pressure, and the environment is good. ●It has a unique effect on the screening and classification of powdery and granular materials. Technical parameter

| Model | size (mm) | Material particle size | Screen inclination | amplitude (mm) | Layers | power(kw) |

| CF-ZXS-520 | 500*2000 | 0.74-10mm | 0°-7° | 4-10 | 1-6 | 2*(0.37-0.75) |

| CF-ZXS-525 | 500*2500 | 2*(0.37-0.75) | ||||

| CF-ZXS-1020 | 1000*2000 | 2*(0.37-0.75) | ||||

| CF-ZXS-1025 | 1000*2500 | 2*(0.37-1.1) | ||||

| CF-ZXS-1030 | 1000*3000 | 2*(1.1-1.5) | ||||

| CF-ZXS-1040 | 1000*4000 | 2*(1.1-1.5) | ||||

| CF-ZXS-1235 | 1200*3500 | 2*(1.1-2.2) | ||||

| CF-ZXS-1250 | 1200*5000 | 2*(1.1-2.2) | ||||

| CF-ZXS-1535 | 1500*3500 | 2*(1.1-2.2) | ||||

| CF-ZXS-1560 | 1500*6000 | 2*(3.7-5.5) |

Product Details

Application range

Sawdust, wood powder, charcoal, activated carbon, carbon black and other fibrous materials, feed processing powder, granules, additives, glass powder beads, alumina, corundum, chlorocarbon, emery. Cereals, corn, beans, sesame. Flour, cocoa, coffee, condiments, additives. Plastics, rubber additives, dyes, fillers.