| Model | Effective area | Effective screen diameter | layers | Motor Power | Related dimensions | cleaning system |

| CF-YBS-112 | 1.13 | 1250 | 1--5 | 2.2kw | 1250*1110 | bouncing ball drum brush Ultrasonic |

| CF-YBS-116 | 1.83 | 1580 | 1--5 | 3kw | 1580/1400 | |

| CF-YBS-118 | 2.43 | 1778 | 1--5 | 3kw | 1778/1412 | |

| CF-YBS-120 | 2.63 | 1880 | 1--5 | 4kw | 1880/1800 | |

| CF-YBS-126 | 5.3 | 2560 | 1--5 | 5.5kw | 2650/1900 |

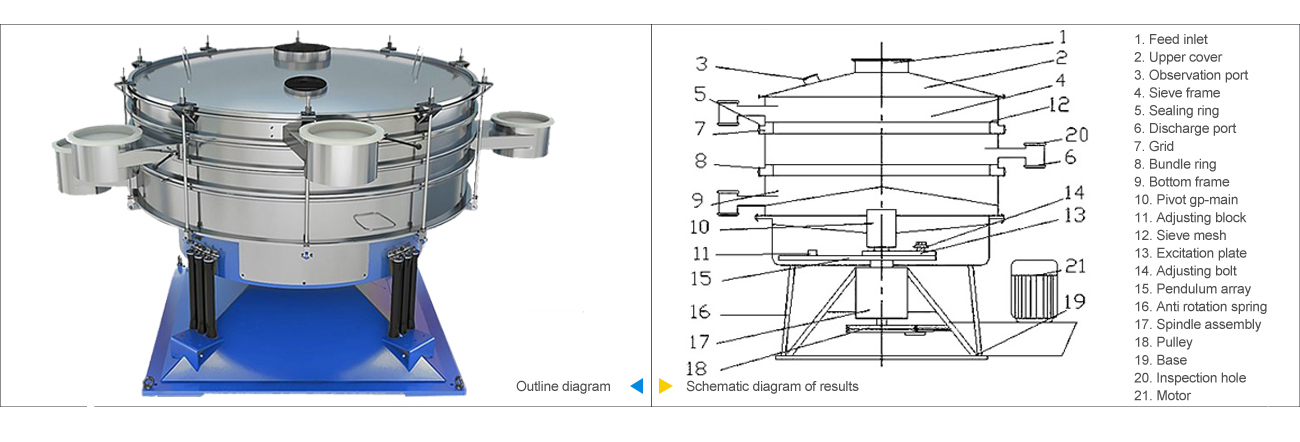

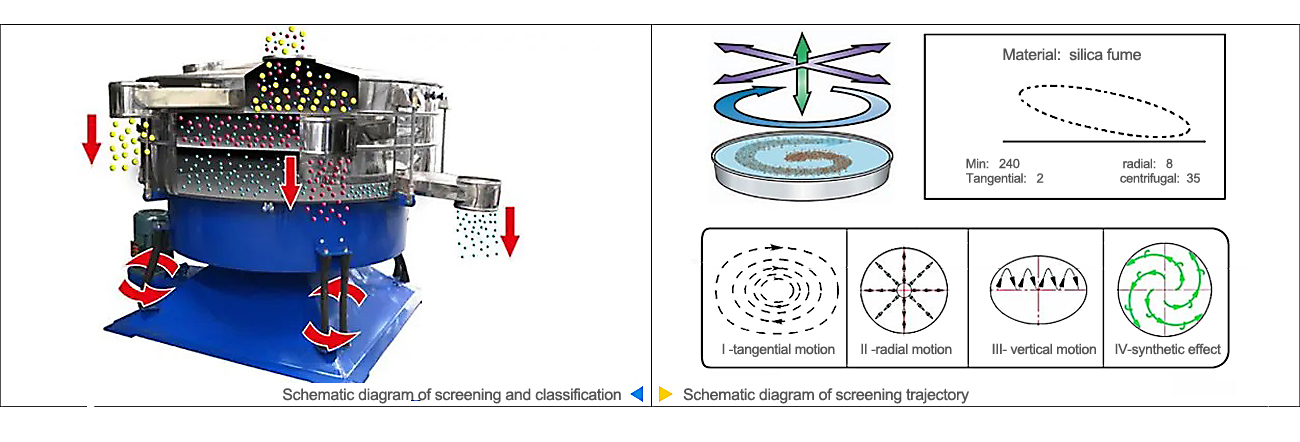

The swing sieve is a low-frequency vibrating screen that directly imitates artificial screening. Its motion trajectory is the combination of the radial displacement of the instantaneous motion and the circular motion of this displacement as the axis. The non-linear three-dimensional motion can be generated by adjusting the eccentric distance of the exciter, and the movement of the material on the screen surface is similar to manual screening, so as to achieve the effect of screening the material. The screen body is equipped with a unique net cleaning device. , in order to achieve effective screening effect, especially suitable for precision screening of cylindrical, flake and other irregular shaped materials.

The swing sieve is a low-frequency vibrating screen that directly imitates artificial screening. Its motion trajectory is the combination of the radial displacement of the instantaneous motion and the circular motion of this displacement as the axis. The non-linear three-dimensional motion can be generated by adjusting the eccentric distance of the exciter, and the movement of the material on the screen surface is similar to manual screening, so as to achieve the effect of screening the material. The screen body is equipped with a unique net cleaning device. , in order to achieve effective screening effect, especially suitable for precision screening of cylindrical, flake and other irregular shaped materials.

Chemical Industry Pharmaceutical Industry Ceramic Abrasive Metallurgical Industry Application material Paint, resin powder, PVC resin powder, citric acid, polyethylene powder, washing powder pharmaceutical intermediates, medical excipients, traditional Chinese medicine powder, traditional Chinese medicine liquid, western medicine powder, western medicine liquid, aluminum silver paste, mud, kaolin, quartz sand , alumina, artificial black aluminum, graphite, silicon carbide, spray soil particles, emery, iron powder, titanium dioxide, electrolytic copper powder, etc.

Chemical Industry Pharmaceutical Industry Ceramic Abrasive Metallurgical Industry Application material Paint, resin powder, PVC resin powder, citric acid, polyethylene powder, washing powder pharmaceutical intermediates, medical excipients, traditional Chinese medicine powder, traditional Chinese medicine liquid, western medicine powder, western medicine liquid, aluminum silver paste, mud, kaolin, quartz sand , alumina, artificial black aluminum, graphite, silicon carbide, spray soil particles, emery, iron powder, titanium dioxide, electrolytic copper powder, etc.