Product Features

1. All the parts in contact with the material of the whole machine are made of 304 stainless steel, and the length design range is 1 meter to 12 meters, which can be customized according to the customer's materials and requirements. The minimum feeding pipe diameter is more than 127MM, and the conveying capacity per hour is at least 800KG. Spindle motor power is determined according to customer requirements and material selection.

2. The distance between the inner wall of the stainless steel feeding tube and the spiral blade is not more than 3MM, the spiral blade is laser-cut, and all welding ports are polished to achieve smoothness and no residual material.

3. The conveying speed is from 100KG to 15 tons per hour.

4. The machine adopts imported universal bearing with heat insulation and dustproof design, both ends of the feeding machine are designed and installed with oil seals imported from Taiwan to ensure that no dust and sundries enter the bearing to improve durability.

5. Scientific design: The screw shaft is made of stainless steel seamless tube, which is corrected by a lathe to ensure concentricity and stable operation of the machine. The blades are all made of thickened stainless steel.

6. The bottom is designed with a material cleaning port. If you need to change the material, you only need to use an air gun to remove the residual material. And a safety switch is designed at the clearing port. Once the clearing door is opened, the power will be cut off, which is safe and reliable.

7. The circuit is designed for overload protection, which effectively protects the motor from burning and is durable. It has the function of stopping when the material is full, and automatically running the material is used up. Just set the material use time, then there will be no need for workers to take care of it.

Applicable materials: It is widely used in the conveying equipment of powder, granule, solid, sheet and broken material in various industries such as chemical industry, plastics, agriculture, food, feed and so on. For example: cement, coal powder, flour, grain, metal powder, etc. The screw feeder is not suitable for conveying materials of nonuniform sizes, liquids, and materials for which integrity is required, such as seeds, tablets, etc.

Things to pay attention to when buying an inclined tube screw conveyor:

1. Materials to be conveyed: preferably dry powder materials, the specific gravity should not be too heavy

2. Inclination angle: 0-90°

3. Conveying length: the larger the inclination angle is, the conveying length should not be too long;

4. Motor power: The motor power to be selected is determined according to the conveying length, inclination angle, and conveying amount. Usually, bigger power is required;

5. Spiral rotation speed: The rotation speed of the screw conveyor is selected according to the inclination angle. The larger the inclination angle, the faster the rotation speed.

Safety Precautions for Screw Conveyors

1. The screw conveyor should start without load, that is, start when there is no material in the casing, and then feed the screw machine after starting.

2. During the initial feeding of the screw conveyor, the feeding speed should be gradually increased to reach the rated conveying capacity, and the feeding should be uniform, otherwise it will easily cause the accumulation of the conveyed material and the overload of the drive device, which will damage the entire machine earlier.

3. In order to ensure that the screw machine starts without load, the conveyor should stop feeding before stopping, and stop running after the material in the casing is completely exhausted.

4. The material to be conveyed must not be mixed with hard bulk materials to avoid screw jamming and damage to the screw machine.

5. In use, check the working status of each part of the screw machine frequently, and pay attention to whether the fastening parts are loose. If the parts are found to be loose, the screws should be tightened immediately.

6. Special attention should be paid to whether the screw between the spiral tube and the connecting shaft is loose. If this phenomenon is found, it should be stopped immediately and corrected.

7. The cover of the screw machine should not be removed when the machine is running to avoid accidents.

8. Any abnormal phenomenon in the operation of the screw machine should be checked and eliminated, and it should not be forced to run.

9. The moving parts of the screw machine should be lubricated frequently.

Internal details

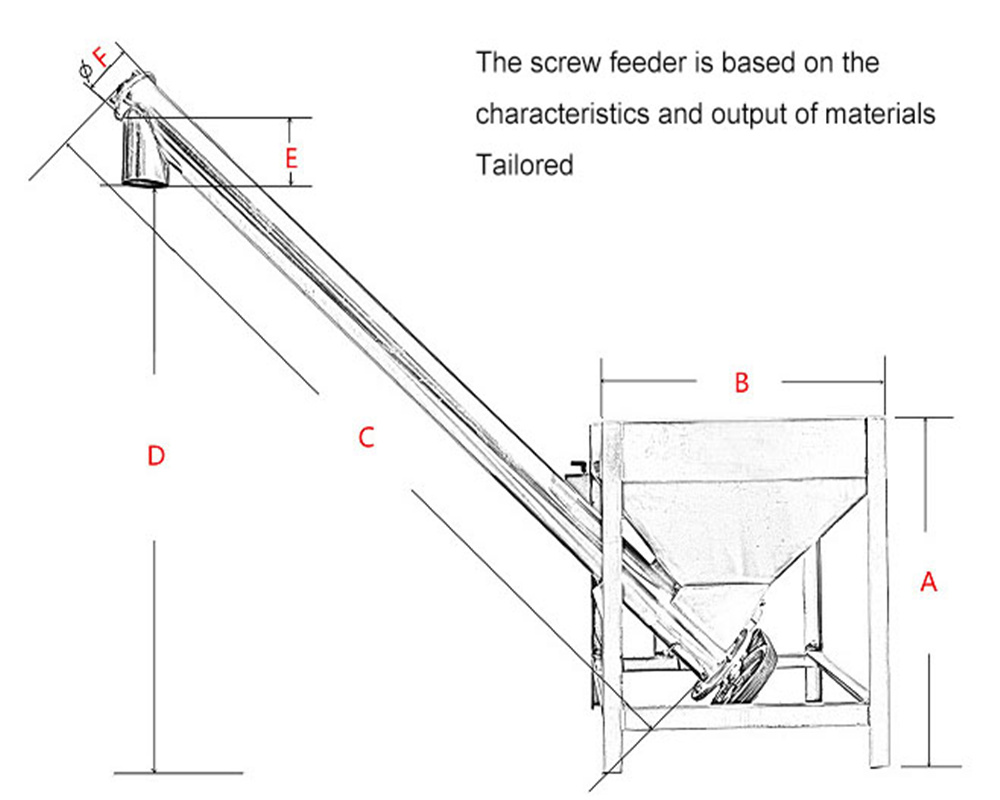

Parameter size

A corner of the workshop

Type of spiral

Applicable materials