Product advantages

● Any particle, powder, mucus can be screened within a certain range.

● Sieve as fine as 1000 mesh or 0.002mm, filter as small as 2 microns.

● Grading sieving, it can screen one to five layers of screen mesh, and can carry out two to six grades of sorting or filtering at the same time.

● High efficiency, compact and durable design, easy to change the screen, easy to operate, easy to clean

● Rotary vibrating screen automatically discharges impurities and coarse materials, and can operate continuously.

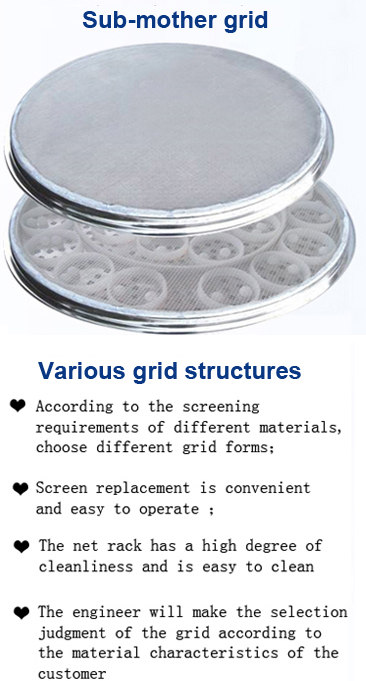

● Mesh frame design, the screen mesh can be used for a long time, and the mesh can be changed quickly, only 3-5 minutes.

● Small size, space saving, easy to move.

| Wide range of screening materials | Screen replacement is easy | Multi-layer classification filter | Save human effort |

| Any particle, powder, mucus can be screened within a certain range | 3-5 minutes can be replaced to complete | Can sieve one to five layers of screen | Sub-mother grid design, less personnel for screen replacement, saving time |

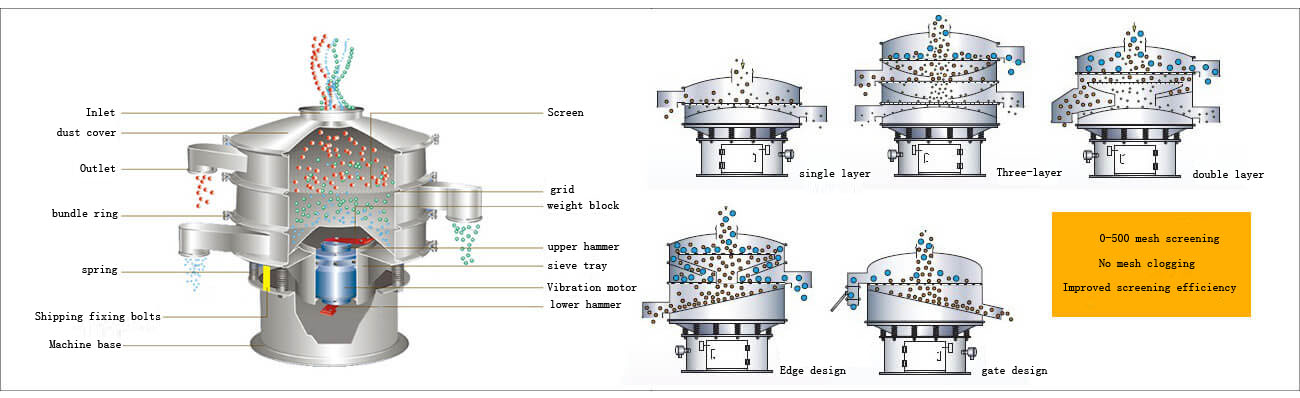

Working principle

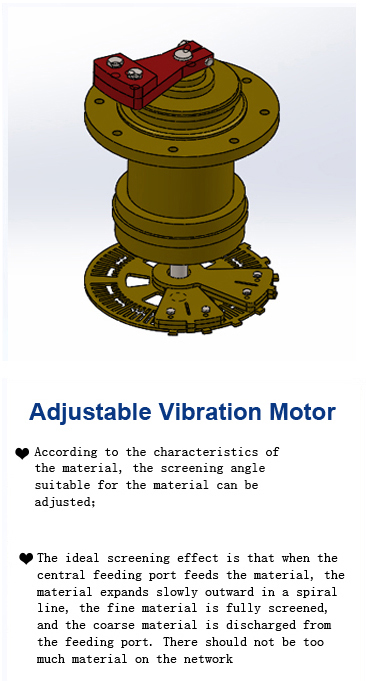

After the rotary vibrating screen is started, its power device is the eccentric blocks at the upper and lower ends of the vibrating motor with different phases. Due to the high-speed placement, a composite inertial force is generated. Under the action of the sieve, it continuously reciprocates, and then drives the screen surface to vibrate periodically, so that the materials on the screen surface move in a directional and active manner with the screen box, during which materials smaller than the screen surface aperture fall to the lower layer through the screen holes. , become the material under the sieve, and the material larger than the aperture of the sieve surface is discharged from the discharge port after continuous jumping motion to complete the screening work. The motion trajectory of the vibrating body of the rotary vibrating screen is a complex three-dimensional curve in space. The projection of this curve on the horizontal plane is a circle, and the projection on the two vertical planes is two identical ellipses. In practical application, by adjusting the relative phase of the eccentric blocks at the upper and lower ends of the vibration motor, the movement trajectory of the material on the screen surface can be changed, so as to achieve different screening operations.

Product features

Technical parameter

| Model | Outer frame diameter(mm) | Screen diameter(mm) | Maximum feed particle size(mm) | Screen mesh | layers | Vibration times | power(KW) |

| CF-XZS-106 | φ600 | 560 | <10 | 2-800 | 1-5 | 1440 | 0.55 |

| CF-XZS-108 | φ800 | 760 | <20 | 2-800 | 1-5 | 1440 | 0.75 |

| CF-XZS-110 | φ1000 | 950 | <20 | 2-800 | 1-5 | 1440 | 1.1 |

| CF-XZS-112 | φ1200 | 1150 | <20 | 2-800 | 1-5 | 1440 | 1.5 |

| CF-XZS-115 | φ1500 | 1430 | <20 | 2-800 | 1-5 | 1440 | 2.2 |

| CF-XZS-118 | φ1800 | 1700 | <30 | 2-800 | 1-5 | 1440 | 3 |

| CF-XZS-120 | φ2000 | 1910 | <30 | 2-800 | 1-5 | 1440 | 4 |

Application material

Materials: Pigment, micropowder, paint, soda ash, lemon powder,Sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar, etc.Coating paint, clay mud, black and white liquid, waste liquid, papermaking liquidTitanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powderChinese medicine powder, Chinese medicine liquid, Western medicine powder, Western medicine liquid, Chinese and Western medicine granules

Raw material granules

Monk fruit

Pb304

Pigment

Opper powder

Flour

Tungsten powder

Plastic particles

Sweetener