Working principle

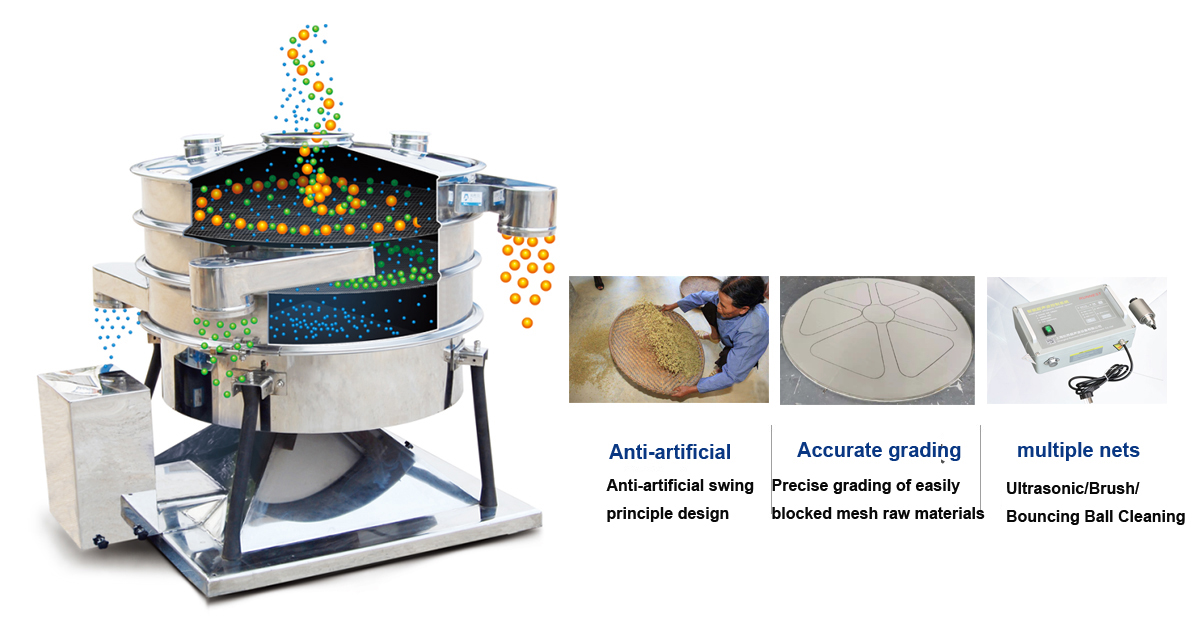

Ultrasonic swing sieve is a kind of low-frequency swing sieve that imitates artificial shaking. The vibrator produces nonlinear three-dimensional motion, and the material also produces the same motion similar to manual operation, so as to achieve the purpose of screening, and with the screening accessories, a more ideal screening effect can be obtained; suitable for round, cylindrical, sheet It can be used for materials that are easy to block and need to be precisely screened.

The ultrasonic swing sieve adopts the motor to drive the belt and the components inside the transmission equipment. The instantaneous movement is the combination of the displacement along the radial direction and the circular movement with this displacement as the axis (the screw movement), and the driving body presents a circular motion during operation. The change of shape and trace makes the material on the screen surface also produce the same movement similar to manual operation, so as to achieve the purpose of screening, and with the screening accessories, a more ideal screening effect can be obtained. The residence time of the material in the screen machine can be adjusted by the radial direction and cutting angle of the oscillating screen toward the driving direction. The motion trajectory is horizontal and throwing and tumbling motion.

Product advantages

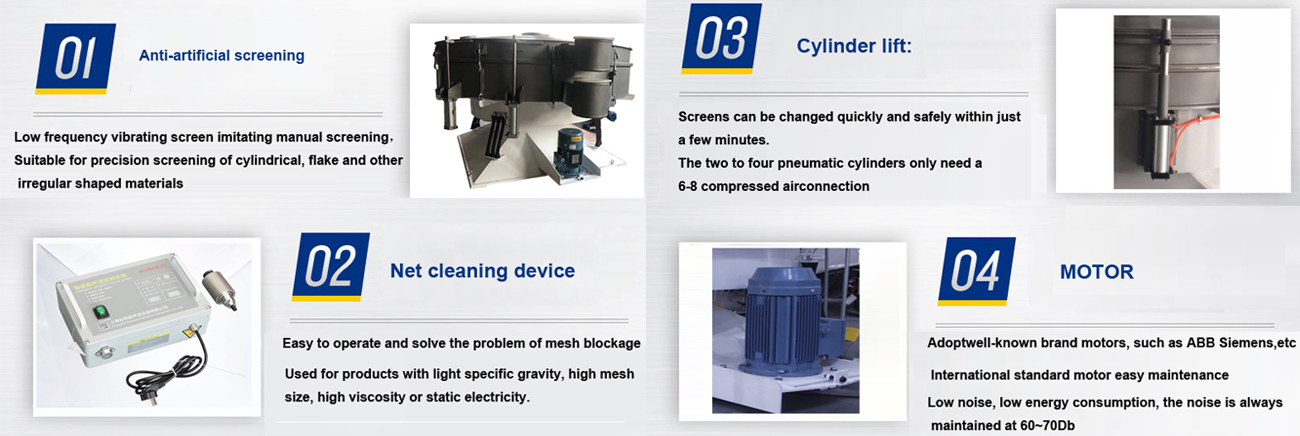

Due to the simple modular design and the characteristics of low-speed operation, the noise of the plane shaker is always maintained at 60 to 70dB, ensuring smooth and quiet operation; using ordinary Y series motors, the minimum mechanical drive is 0.25KW, weighing 2 tons. The largest model only needs 5.5KW of power.Absolute dustproof operation

In addition to the ventilation system already present on site, the swing screen does not require any auxiliary devices for air purification or dust collection. The system can have its own airtight and vacuum design, as well as nitrogen purification.

Structural principle of swing sieve

● Basic rotary motion is similar to manual screening. Eccentricity adjustable from 25 to 40mm, low speed V-belt drive adjustable from 120 to 360rpm.

● The residence time of each product can be adjusted toward the drive axis through the radial and cutting angles of the oscillating screen.

● Therefore establish a three-dimensional tumbling motion for leveling and throwing. The material is evenly dispersed on the entire screen surface from the center to the outer edge, so as to spread in the axial direction in a spiral motion. The fine particles thus complete the entire sieving process.

● The horizontal and vertical acceleration increases with the movement of the particles, and the particles close to the mesh size are successfully separated; the larger particles are transported to the outlet, and the flow is controlled by an adjustable guide device, which controls the flow rate. Another factor for material residence time.

● This process is repeated between each sieve layer.

Technical parameter

| Model | Effective area | Effective screen diameter | layers | Motor Power | Related dimensions | cleaning system |

| JX-CYBS-112 | 1.13 | 1250 | 1--5 | 2.2kw | 1250*1110 | bouncing ball drum brush ultrasonic |

| JX-CYBS-116 | 1.83 | 1580 | 1--5 | 3kw | 1580/1400 | |

| JX-CYBS-118 | 2.43 | 1778 | 1--5 | 3kw | 1778/1412 | |

| JX-CYBS-120 | 2.63 | 1880 | 1--5 | 4kw | 1880/1800 | |

| JX-CYBS-126 | 5.3 | 2560 | 1--5 | 5.5kw | 2650/1900 |

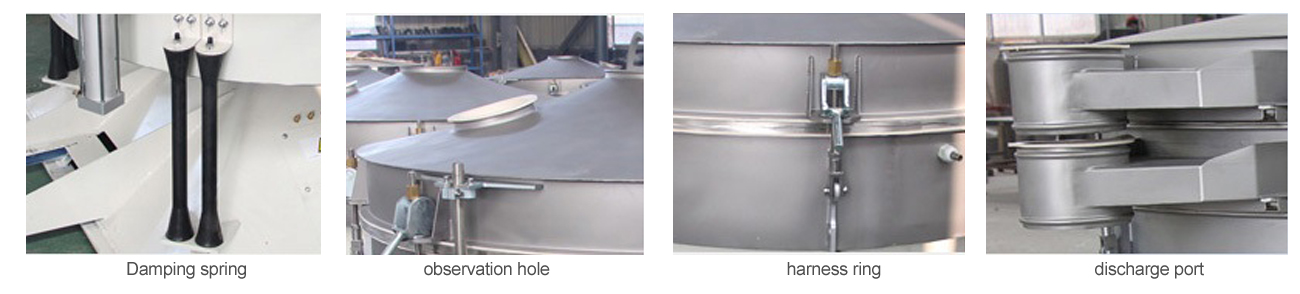

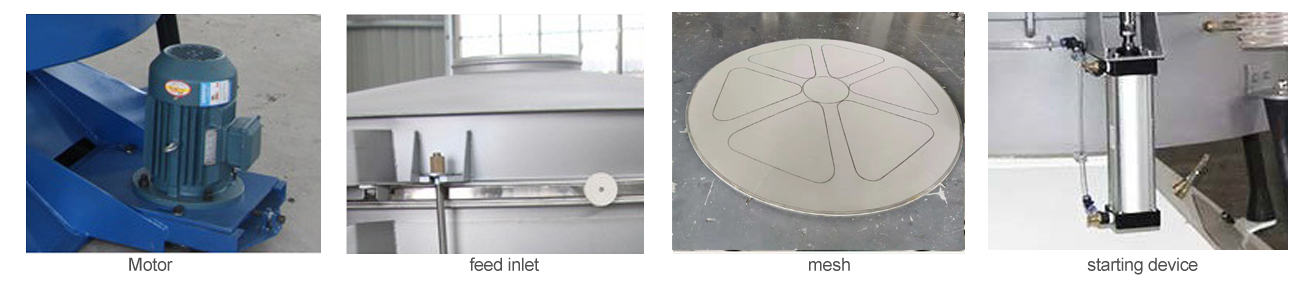

Product details

Application range

Chemical Industry Pharmaceutical Industry Ceramic Abrasive Metallurgical Industry

Application material

Ultrasonic swing sieve is widely used in chemical, pharmaceutical, food and spices, tea, feed, plastic, rubber, fertilizer, sugar and salt industry, renewable resources, EPS, PVI, PVC, resin and other industries to polarize fine materials and other operations.